Key Takeaways

- PP (polypropylene) sintered cartridges are a solid bet for many aqueous acids, bases, salts, detergents, and process-water streams—especially at moderate temperature.

- PP’s biggest enemies are strong oxidizers, certain solvent families, and the sneaky assassin called environmental stress cracking (ESC).

- Compatibility is never a simple “yes/no.” It’s concentration × temperature × time × mechanical stress × cleaning cycles.

- Most failures aren’t dramatic melting. They’re boring—and expensive: swelling, embrittlement, micro-cracking, seal leaks, bypass.

- If you can’t validate compatibility, do a soak test + hot soak + stressed soak. Cheap insurance. I’d rather break a coupon than a production schedule.

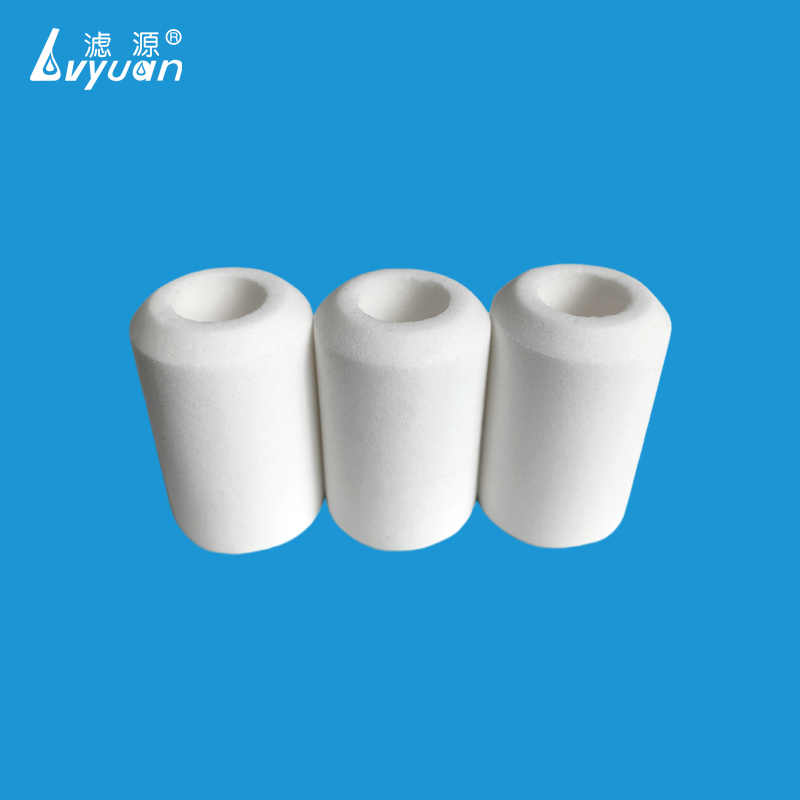

Introduction

If you came here asking, “Is PP chemically compatible?” I’m going to answer the question you actually mean: “Will a PP sintered filter cartridge survive my real process—at my concentration, my temperature, my ΔP, my cleaning routine—without turning into a leak, a bypass path, or a hairline-crack surprise?”

Here’s the direct answer: PP sintered filter cartridges handle a wide range of water-based chemicals—many acids, bases, salts, and detergents—very well, particularly at moderate temperatures. Where PP gets into trouble is with strong oxidizing environments (think aggressive chlorine chemistry), some chlorinated and aromatic solvents, and any setup where chemical exposure plus mechanical load triggers environmental stress cracking (ESC). If you’ve ever said, “But the compatibility chart said OK,” you’re already in the right article.

Let’s make this predictable—so you don’t learn polymer science from a shutdown.

Why PP Is the Default Material (And Why That’s Not an Insult)

PP is popular because it’s the rare material that’s good at many things without demanding a luxury budget.

- It’s a commodity polymer with mature supply chains and consistent grades

- It has broad chemical resistance in many industrial aqueous environments

- As a sintered porous body, it offers rigid structure and depth capture behavior

- It’s usually cost-effective across a cartridge’s service life, not just the purchase order

I honestly believe “default” is underrated. In filtration, drama is expensive. PP is often the no-drama choice—until you put it in a situation that’s basically polymer torture.

Chemical Compatibility Isn’t a Chart. It’s a Story With Five Plot Twists

A compatibility chart is a snapshot. Your process is a movie.

H2: The five variables that change everything

- Concentration (2% and 30% are not cousins—they’re strangers)

- Temperature (heat accelerates degradation like gasoline accelerates gossip)

- Exposure time (a rinse vs continuous service is a whole different life)

- Mechanical stress (ΔP, clamping force, vibration, pump cycling)

- Cleaning cycles (CIP/SIP, solvents, oxidizers, thermal shocks)

If you ignore #2–#5, you’re not doing compatibility. You’re doing optimism.

What PP Sintered Filter Cartridges Handle Well

H2: Aqueous Process Streams (PP’s Comfort Zone)

If your fluid is mostly water—process water, rinse water, brines, many detergents—PP usually behaves.

PP is commonly used for:

- Process water filtration

- Salt solutions / brines

- Many detergents and surfactant-based cleaners (within reasonable limits)

- General particulate filtration in water-like streams

Why it works: PP’s chemical structure is fairly stable in a lot of aqueous environments, and the sintered form gives you a robust, self-supporting porous network.

H2: Many Acids and Bases (With Common-Sense Boundaries)

In countless real plants, PP is used around:

- Hydrochloric acid in many conditions

- Sulfuric acid in many conditions

- Sodium hydroxide / potassium hydroxide in many conditions

But I’m not going to pretend it’s universal. The real-world outcome depends on concentration and temperature. A “compatible” material at room temp can become “why is the seal leaking?” material at 70°C.

H2: Some Alcohols and Mild Solvent Exposure (Case-by-Case)

PP often tolerates common alcohols (like IPA or ethanol) in many setups. But once you say “solvent,” you’re opening a zoo. And some animals eat plastic.

What PP Does NOT Handle Well (Where People Get Burned)

H2: Strong Oxidizers (PP’s Bad Neighborhood)

Strong oxidizing environments are where PP can lose toughness over time—sometimes quietly.

Red flags include:

- Aggressive chlorine-based oxidizers (concentration and temperature matter a lot)

- Oxidizing acids at high strength

- High-intensity peroxide systems (depends on conditions)

Even if the PP doesn’t dissolve, oxidizers can cause embrittlement, which is the polite word for “it cracks when you touch it.”

H2: Chlorinated Solvents (Often Risky)

Chlorinated solvents are notorious for attacking many polymers. PP can suffer swelling or stress cracking in certain chlorinated solvent exposures—especially with heat and load.

Does that mean “never”? Not automatically. It means don’t assume. Test.

H2: Aromatic Hydrocarbons (Common Trouble)

Aromatics (like toluene and xylene) can be problematic for PP depending on concentration, temperature, and exposure time.

If your process smells like a paint booth, PP might not be the hero.

H2: Environmental Stress Cracking (ESC): The Failure Mode People Misdiagnose

ESC is the sneakiest way PP fails.

Here’s the pattern:

- In a static soak test, PP looks fine.

- In real service, the cartridge is under clamping force and ΔP cycles.

- A chemical acts as a cracking agent under stress.

- You get micro-cracks → leaks → bypass → “quality problem.”

And everyone argues about “material quality” while the real culprit is stress + chemistry.

How PP Fails in the Real World (So You Can Spot It Early)

H2: Swelling → Dimensional Drift → Seal Leaks → Bypass

Symptoms:

- the cartridge fits… then doesn’t

- O-rings behave weirdly

- downstream solids appear while ΔP looks “normal”

Swelling doesn’t need to be dramatic to ruin your day. A millimeter can become a bypass highway.

H2: Embrittlement → Cracking During Maintenance

Symptoms:

- brittle feel

- chips or fractures around stress points

- failures after cleaning cycles or oxidizer exposure

H2: Surface Changes → Wetting/Flow Oddities

Sometimes the surface energy changes, and suddenly:

- wet-out gets worse

- air entrapment rises

- flow becomes inconsistent

It’s less common, but it’s real.

How to Validate PP Chemical Compatibility (Without Gambling Your Production)

If you have a lab, great. If you don’t, you can still do something that works.

H2: The “Soak + Hot Soak + Stressed Soak” Method

- Room-temperature soak

- Use real concentration. Real chemical. Real time window.

- Measure weight and dimensions.

- Hot soak

- Repeat at operating temperature (or slightly above).

- Heat accelerates incompatibility. Fast.

- Stressed soak

- Apply mechanical stress while soaking: compression, bending, clamping.

- This is where ESC shows up.

- Cleaning-cycle simulation

- If you do CIP, include your cleaning chemistry and temperature.

- Compatibility must cover the full lifecycle, not just the process fluid.

H3: What to measure (don’t just eyeball it)

- weight change

- OD/ID/length change

- surface cracking under magnification

- brittleness (careful bend test)

- simple flow/ΔP comparison if you can rig a small loop

If the process is expensive, the testing should be boring. Boring is good.

When PP Is the Right Choice (And When It Isn’t)

H2: Choose PP sintered cartridges when…

- your stream is aqueous and moderately chemical

- you need broad compatibility without PTFE pricing

- temperatures are reasonable and ΔP is controlled

- you want a rigid porous element that won’t collapse under normal conditions

H2: Consider alternatives when…

- oxidizers dominate the chemistry

- solvents are aggressive or unknown blends

- temperatures and ΔP cycling are high

- failure consequences are severe (purity-critical, safety-critical)

Switching materials isn’t defeat. It’s adult decision-making.

FAQ (People Also Ask)

Are PP sintered filter cartridges chemically resistant?

Yes—PP is resistant to many aqueous chemicals, acids, bases, and salts, especially at moderate temperatures. It can struggle with strong oxidizers and certain solvents.

What chemicals are not compatible with polypropylene filters?

Strong oxidizers are a major risk. Certain chlorinated solvents and aromatic hydrocarbons can also cause swelling or stress cracking depending on conditions.

Can polypropylene filters handle hydrochloric acid or sodium hydroxide?

Often yes, in many industrial conditions. But concentration, temperature, exposure time, and mechanical stress still matter—validate for your exact process.

Why do PP filters crack even if the chart says “OK”?

Environmental stress cracking (ESC). Static charts don’t account for ΔP cycles, clamping force, vibration, or real cleaning routines.

How do I test chemical compatibility for PP sintered cartridges?

Use a practical validation approach: soak at real concentration, repeat at operating temperature, add mechanical stress to simulate real service, and measure weight/dimensions plus inspect for cracking.

The Bottom Line

PP sintered filter cartridges are popular because they’re genuinely useful: broad compatibility in many aqueous systems, decent stability, and good value. But PP is not a superhero. Strong oxidizers, certain solvent families, and ESC under mechanical load can turn “works fine” into “why is the system leaking?”

If you want fewer surprises, stop asking “Is PP compatible?” and start asking: Compatible at what concentration, temperature, time, stress, and cleaning cycle?

Paste your Internal Links JSON and I’ll produce the strict-linked version with 5–8 natural internal links using your exact keywords and URLs.