Key Takeaways

- PE sintered filter cartridges are best when you need toughness, stable pore structure, and repeatable filtration in water-like or mildly chemical streams.

- Their “real” temperature limit is rarely a single number—it’s temperature + differential pressure (ΔP) + time. Heat alone isn’t the whole villain.

- PE shines in water treatment, OEM equipment, pneumatics, pre-filtration, and abrasive-ish service where fragile media tends to fold.

- The fastest way to choose wrong is to shop by micron rating only. You need flow, ΔP, viscosity, and contaminant type.

- If your process involves aggressive solvents or sustained high temperature, PE may be the wrong hero—PP or PTFE often step in.

Introduction

If you’re here, you’re probably asking some very practical questions: What are PE sintered filter cartridges actually good for? Where do they fail? How hot is “too hot”? Good. Those are the questions that save you money.

Here’s the direct answer: PE sintered filter cartridges are best for industrial filtration where mechanical toughness, consistent pore structure, and predictable flow matter more than extreme chemical resistance or high-temperature performance. They’re excellent in water treatment, general process filtration, utility streams, and OEM modules—especially when you want a rigid, cleanable filter body. But temperature limits depend on your system’s ΔP and runtime, and harsh solvents can push PE out of its comfort zone fast.

Now let’s unpack that with the kind of detail suppliers’ one-page PDFs magically forget.

What Is a PE Sintered Filter Cartridge (In Plain English)?

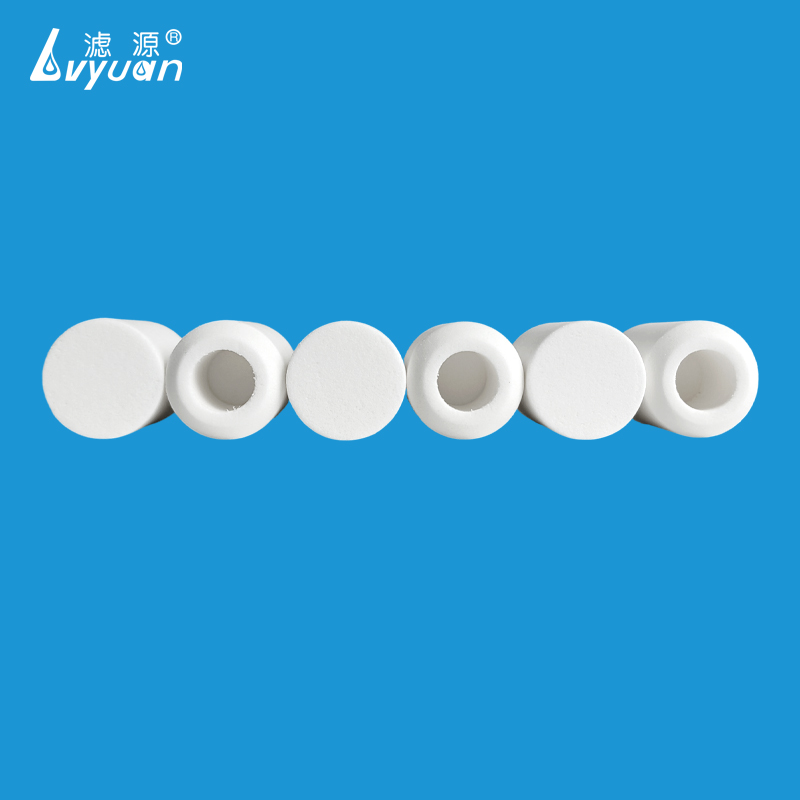

A PE sintered filter cartridge is made by fusing polyethylene powder particles together—heat them until they bond at contact points, but don’t melt into a solid brick. The result is a rigid, porous structure with interconnected pathways.

Think of it like a sponge made from plastic beads that decided to hold hands permanently.

This gives you:

- Depth filtration behavior (particles capture within the structure, not just on the surface)

- A self-supporting body (no pleats collapsing, no media delaminating)

- A pore network that can be engineered by powder size and sintering conditions

This is why PE is popular in the “industrial reality” category: vibration, pulsing flow, rough handling, and systems that don’t run gently.

Best Uses for PE Sintered Filter Cartridges (Where They Truly Earn Their Keep)

H2: 1) Water & Wastewater Filtration (The Home Turf)

If your stream is basically water—with solids, rust, scale, sand, or general unpleasantness—PE is often a very sensible pick.

Typical roles:

- Pre-filtration before membranes

- Protection for spray nozzles and valves

- Solids control in recirculating loops

- Cooling water and rinse water filtration (application-dependent)

Why PE works here: stable pores, good mechanical resilience, and a flow/ΔP balance that often stays predictable over time.

H2: 2) OEM Filtration Modules (When You’re Building a Product, Not Just Buying a Part)

I’ve said it before and I’ll say it again: OEMs don’t just buy filters—they buy predictability and ease of integration.

PE sintered elements can be made into:

- cylinders, cups, discs, cones

- custom shapes that double as a structural part

- molded interfaces and rigid housings

If you’re designing a system, PE is often easier to build around than fragile media.

H2: 3) Pneumatic / Air Intake Protection (Moderate Conditions)

In air or gas filtration where temperatures are moderate and contaminants are particulate:

- dust capture

- intake protection

- compressor accessory filtration (design dependent)

PE’s rigidity helps in environments where vibration and pulsing are normal, not occasional.

H2: 4) Mild Chemical Process Filtration (The “Know Your Chemistry” Zone)

PE can work well in many mild aqueous chemicals. But “mild” is doing a lot of work in that sentence.

PE is not the “aggressive solvent champion.” If the chemistry gets spicy, you start looking at PP or PTFE.

H2: 5) Applications With Frequent Handling, Cleaning, or Replacement

Some plants treat filters like consumables. Others want cleanability and reuse.

PE’s tough structure often tolerates:

- backwashing (in suitable designs)

- ultrasonic cleaning (in some cases)

- compatible chemical rinsing

But don’t assume “cleanable” means “immortal.” If the contaminant is oily, sticky, or gelatinous, cleaning becomes performance art.

Temperature Limits: The Honest Conversation Nobody Puts on the Datasheet

Let’s talk about the question you really mean: “At what temperature will this thing stop behaving?”

Here’s the rule I use in the field:

H2: Temperature limit = Temperature × ΔP × Time

Heat alone isn’t always the killer. Heat + stress is.

- At higher temperatures, PE can soften and become more prone to creep (slow deformation).

- High differential pressure (ΔP) adds compressive load.

- Long runtime means more time for the polymer to “relax” under stress.

So if you run:

- moderate temperature + low ΔP = usually fine

- moderate temperature + high ΔP + long cycles = you might see deformation

- high temperature + high ΔP = PE starts negotiating, and not in your favor

H3: Practical signs you’re pushing the limit

- seals start leaking because dimensions drift

- the cartridge becomes slightly out-of-round

- ΔP behavior changes even when solids loading looks normal

- flow drops earlier than expected across repeated cycles

If you see these, don’t just blame “clogging.” It might be material mechanics.

H3: What to do if you need more temperature headroom

- increase filtration area (lower face velocity = less ΔP stress)

- use thicker walls or better support in the housing

- consider moving to PP or PTFE depending on chemistry

Typical Industries Using PE Sintered Filter Cartridges

H2: Water Treatment & Utilities

- municipal and industrial water

- pre-filtration before RO/UF

- particulate control in process loops

H2: Food & Beverage (Mostly Utility Streams and Pre-Filtration)

- process water filtration

- rinse water, brine handling (depending on conditions)

- protection for nozzles and downstream filters

For direct product-contact filtration, selection becomes more regulatory and validation-heavy (and sometimes other polymers/media types make more sense). But PE absolutely shows up in the supporting infrastructure.

H2: Chemical Processing (Mild to Moderate Chemistry)

- general particulate filtration

- recirculating solutions with known compatibility

- filtration where mechanical strength matters

When chemicals turn aggressive, PE usually steps aside for PP/PTFE.

H2: Automotive & Manufacturing

- coolant filtration

- washer systems

- particulate control in industrial fluids

H2: Environmental, Dust, and Air Handling (Moderate Temperatures)

- vent filtration

- intake protection

- dust capture in industrial environments

The Two Traps That Make PE Look Bad (When It’s Actually the System)

H2: Trap #1 — Spec’ing by Micron Rating Alone

“10 micron PE filter cartridge.” Great. Now answer:

- at what flow rate?

- at what ΔP?

- with what viscosity?

- with what solids loading?

- with what contaminant type?

A filter is a restriction in a system. If you ignore system conditions, you’ll keep buying the same mistake in different packaging.

H2: Trap #2 — Ignoring Contaminant Personality

Hard grit behaves differently than:

- fibrous particles

- sticky resins

- oils and fats

- gels and colloids

Depth filters love some of these. Others cause rapid surface blinding and ΔP spikes. If your contaminant smears, you’ll clog pores fast—no matter how tough the polymer is.

How to Choose the Right PE Sintered Cartridge (My “Stop Guessing” Checklist)

H2: Give your supplier (or your engineer brain) these specs

- Fluid identity + concentration

- Operating temperature range

- Target flow rate

- Allowed ΔP (start-of-run and end-of-run)

- Contaminant type and approximate size range

- Solids loading profile (steady vs spiky)

- Cleaning method and frequency

- Geometry constraints (OD/ID/length, end connections)

If you can provide those, you get a filter recommendation worth trusting. If you can’t, you can still move forward—but you should plan for a pilot test.

H3: Pilot test like you mean it

Measure:

- initial ΔP and flow

- ΔP rise curve over time

- retention/quality metric (turbidity, particle counts, visual defects)

- cleanability and recovery (if reuse matters)

Filters don’t fail in PowerPoints. They fail in production. Test there.

FAQ (People Also Ask)

What are PE sintered filter cartridges used for?

They’re commonly used for particulate filtration in water treatment, process utilities, pre-filtration before membranes, OEM filtration modules, and moderate air/gas filtration—especially where toughness and stable pore structure matter.

What is the temperature limit of a PE sintered filter cartridge?

There isn’t one universal number. The practical limit depends on temperature + differential pressure + runtime. Higher temperature under sustained ΔP can lead to creep or dimensional change. Always validate under real operating conditions.

Are PE sintered cartridges chemical resistant?

They can be resistant in many mild aqueous environments, but harsh solvents and strong oxidizers can be problematic. For more aggressive chemistry, PP or PTFE is often safer.

Can PE sintered cartridges be cleaned and reused?

Often yes, depending on contaminant type and cleaning method. Backwashing and ultrasonic cleaning can work in some applications, but oily or sticky contaminants may limit successful reuse.

How do I choose the right micron rating for PE sintered cartridges?

Start with the particle size you need to remove, then validate with flow rate and ΔP requirements. Micron rating alone is not enough—porosity, wall thickness, and dirt-holding capacity matter.

The Bottom Line

PE sintered filter cartridges are the kind of filtration solution I trust when the world is messy: vibration, inconsistent solids, and systems that don’t run gently. They’re tough, stable, and easy to integrate—especially in water-like streams and pre-filtration roles.

But PE has boundaries. Heat plus pressure over time can cause creep. Aggressive solvents can cause swelling or cracking. If your process lives in that zone, don’t force PE to be a superhero it isn’t—choose PP or PTFE and sleep better.

If you paste your Internal Links JSON, I’ll revise this article instantly with 5–8 exact keyword internal links placed naturally, and I’ll also tailor the “temperature limits” section to your typical customer conditions (water treatment? chemical transfer? food processing utilities?) so it reads like it was written inside the plant, not outside it.