Key Takeaways

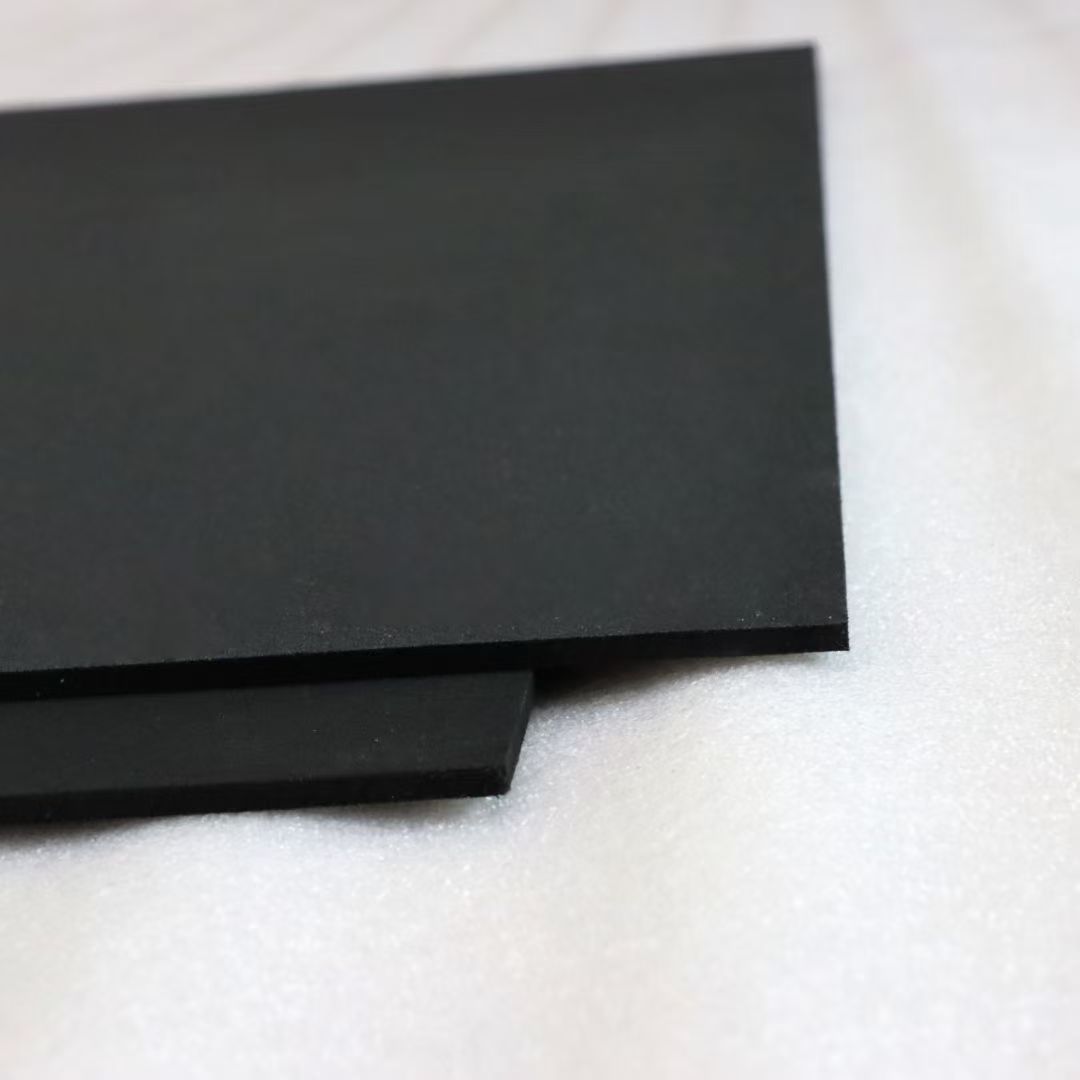

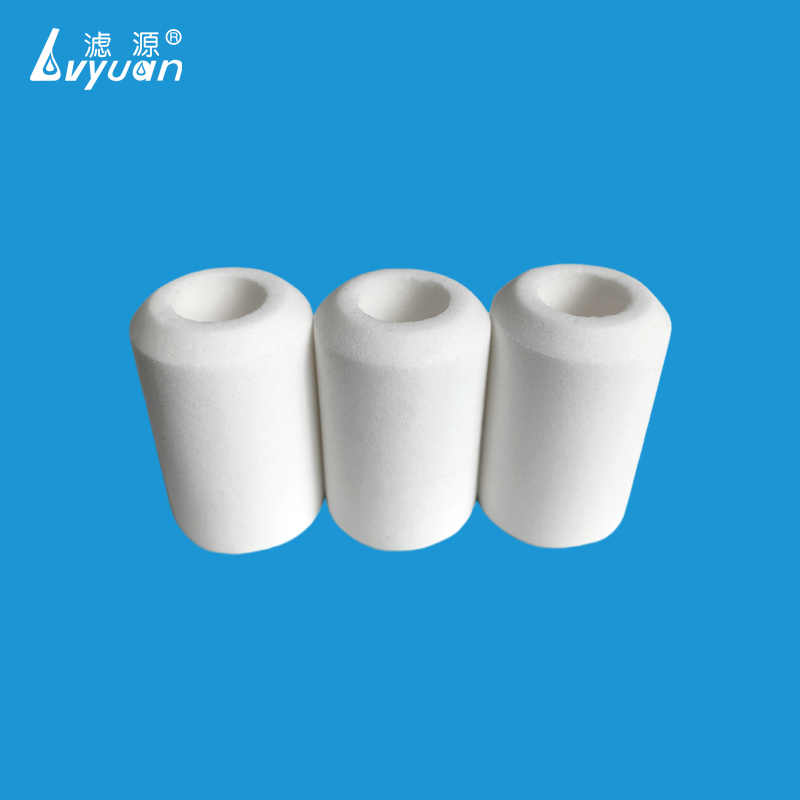

- Nylon (PA) sintered cartridges often outperform PP and PE when you need higher mechanical strength, abrasion resistance, and better wetting in water-based filtration.

- PA’s biggest “superpower” is also its biggest headache: it absorbs moisture, which can change dimensions and mechanical behavior.

- If your process has vibration, pressure pulses, gritty solids, or frequent handling, PA can feel like the grown-up choice—if chemistry and water uptake are controlled.

- PP and PE can still beat PA on cost and certain chemical resistance scenarios—especially when moisture stability matters.

- Choose PA with a system mindset: temperature + ΔP + contaminant type + cleaning chemistry + moisture exposure decides success.

Introduction

If you’re comparing PA (nylon) sintered filter cartridges with PP and PE, you’re usually chasing one of three things: strength, abrasion resistance, or better behavior in water-based systems. Here’s the direct answer: nylon sintered cartridges often outperform PP and PE when the filtration environment includes mechanical abuse (vibration, pressure pulses, rough handling), abrasive solids, or when you need a more hydrophilic surface that wets out easily in aqueous filtration. But nylon has a personality: it absorbs water. That can mean dimensional changes, seal drift, and performance shifts if you ignore it. Pick PA for the right reasons—and design around its quirks—and it can be a brilliant upgrade. Treat it like “PP but stronger,” and it will humble you.

Let’s get into the real-world decision logic.

Why Nylon (PA) Is Different From PP and PE (And Why That Matters)

PP and PE are generally more hydrophobic. Nylon, by comparison, is more polar and tends to behave more hydrophilic. That sounds like chemistry trivia—until you’ve watched a hydrophobic filter refuse to wet out while your pump complains loudly.

PA also brings stronger mechanical properties to the table in many designs:

- higher stiffness

- better abrasion resistance

- better wear behavior in particle-heavy streams

But nylon isn’t a superhero. It’s a specialist.

Here’s the mistake I see all the time: people compare materials like they’re choosing phone cases. “This one is tougher.” Done.

Filtration isn’t a phone case. It’s a stress test.

H2: 1) When Wetting Matters (Aqueous Filtration Without the Drama)

If your system is water-based and you’ve dealt with:

- slow wet-out

- air entrapment

- inconsistent startup flow

- “why is ΔP weird for the first 20 minutes?” moments

…nylon can be refreshing. PA’s more hydrophilic nature can help water wet the pore network more readily, which can translate into more stable early-run behavior.

Is it always night-and-day? No. But in some systems, it’s the difference between “smooth” and “why are we babysitting this filter?”

H2: 2) When the Contaminants Are Abrasive (Grit, Scale, Hard Particles)

Abrasive particles don’t just clog filters—they erode them. Over time, erosion changes pore geometry and performance.

Nylon often performs well in abrasive environments because it tends to resist wear better than many commodity plastics in comparable designs. This is especially relevant when:

- particle hardness is high

- flow velocity is high

- you run long cycles and care about performance drift

If you’re filtering “industrial sandpaper,” PA deserves a look.

H2: 3) When Mechanical Abuse Is Real (Pulses, Vibration, Rough Handling)

Plants don’t run like textbooks. Pumps cycle, valves chatter, operators tighten things “until it feels right.”

PA’s mechanical strength can be a big advantage when:

- ΔP cycles are frequent

- vibration is constant

- cartridges are swapped often

- the housing alignment isn’t always perfect

PP and PE can be excellent too—but PA often feels more confident in physically demanding scenarios.

H2: 4) When You Need Higher Temperature Stability (In Certain Practical Ranges)

This is nuanced. I’m not claiming nylon beats PTFE at high temperature—it doesn’t. But compared to PE (and sometimes PP depending on conditions), PA can offer a more stable mechanical response in certain warm processes.

The deciding factor is still: temperature × ΔP × time (Yes, the “creep math” shows up again.)

The PA “Gotchas” (Nylon’s Personality Traits)

H2: Gotcha #1 — Moisture Absorption (The Feature That Bites)

Nylon absorbs water. That’s not a rumor. It’s how the polymer behaves.

What that can cause:

- dimensional changes (OD/ID shifts)

- seal compression changes → leaks or bypass

- mechanical property changes (sometimes softer, sometimes different stiffness response)

- variability between “dry” storage and “wet” service

If you’re running a tight-tolerance housing and your seals are unforgiving, moisture absorption can turn into a maintenance mystery.

H3: How to reduce the pain

- design seals to tolerate small dimensional shifts

- pre-condition the cartridge in a controlled way (process-dependent)

- validate performance “wet,” not just right-out-of-box

- avoid using nylon where dimensional stability is absolutely critical and uncontrolled moisture exposure exists

H2: Gotcha #2 — Chemical Compatibility Isn’t Automatically Better

People assume “stronger” means “more chemical resistant.” Not necessarily.

Nylon can be excellent in some environments and poor in others. Chemical compatibility depends on:

- specific nylon grade (PA6, PA66, etc.)

- concentration, temperature, and exposure time

- presence of solvents that attack nylon

- cleaning chemistry and cycles

If you’re filtering aggressive solvents, PA may not be the right pick—PTFE often owns that category.

H2: Gotcha #3 — Hydrolysis and Heat (Long-Term Harsh Aqueous Heat)

Certain hot aqueous environments over long durations can be unfriendly to nylon. This is a “validate it” situation, not a “trust vibes” situation.

Practical Comparison: PA vs PP vs PE (How I’d Choose on a Call)

H2: Choose PA (nylon) when…

- you need abrasion resistance in particulate-heavy streams

- you want better wetting in water-based filtration

- mechanical abuse is high (pulsing, vibration, frequent handling)

- you can manage moisture absorption effects (housing/seals/design)

H2: Choose PP when…

- you want broad industrial versatility and cost control

- your chemistry is mostly aqueous with many acids/bases/salts (within limits)

- you want a reliable “default” material with mature supply chain

- oxidizers/solvent risks are understood and managed

H2: Choose PE when…

- toughness and impact resistance matter in moderate conditions

- you want a robust, practical filter for water-like streams

- temperature and chemistry are not extreme

- you want cost-effective durability without nylon’s moisture quirks

Typical Industries Where Nylon Sintered Cartridges Shine

- coolant filtration (application-dependent)

- abrasive particulate removal

- protection for nozzles and downstream equipment

H2: Water-Based Systems Where Wetting Stability Matters

- process water filtration with tricky startup behavior

- systems sensitive to air entrapment and flow instability

H2: Particle-Heavy Industrial Streams

- recirculating loops with grit/scale

- filtration protecting instrumentation and valves

How to Spec PA Sintered Cartridges (So You Don’t Accidentally Create Problems)

H2: The “don’t blame the filter later” checklist

- Fluid identity + concentration

- Temperature profile (normal + spikes)

- Target flow rate

- Allowable ΔP (initial + end-of-run)

- Contaminant type (hard grit vs soft gels vs fibrous solids)

- Moisture exposure expectations (dry storage vs wet service)

- Cleaning chemistry + cycles (CIP, detergents, hot rinses)

- Housing tolerances and seal design

H3: A quick field test I actually trust

Do a short pilot:

- measure initial ΔP and flow

- watch ΔP rise curve

- repeat after cleaning (if reuse matters)

- compare behavior “dry installed” vs “pre-wet installed” if wetting stability is a concern

If the performance changes drastically between dry and wet, that’s not “bad.” It’s information. Use it.

FAQ (People Also Ask)

PA often outperforms PP and PE when you need higher mechanical strength, better abrasion resistance, and more reliable wetting behavior in water-based filtration—especially in systems with pressure pulses or vibration.

Is nylon more hydrophilic than PP or PE?

Generally yes. Nylon tends to wet out more easily in aqueous systems compared with more hydrophobic polymers like PP and PE, which can reduce air entrapment and startup flow instability.

What is the downside of PA sintered filter cartridges?

The biggest downside is moisture absorption, which can cause dimensional and performance changes. Chemical compatibility is also highly application-dependent and must be validated.

Are nylon sintered filters good for abrasive particles?

Often yes—nylon can provide strong wear resistance in particle-heavy streams, which can help maintain filtration performance over longer runs.

Should I choose PA for high-temperature chemical filtration?

Not automatically. PA can handle certain warm applications well, but for aggressive solvents or very high temperatures, PTFE or other engineering polymers may be more appropriate depending on chemistry and design constraints.

Final Thoughts

Nylon sintered cartridges are the kind of upgrade you choose when you’re tired of “mostly fine” performance and you want something that behaves better under real industrial stress—abrasive solids, pressure pulses, and water-based wetting quirks.

But nylon isn’t a free lunch. It absorbs moisture, and that can change the game if your housing and seals don’t allow for it. If you design around that reality, PA can absolutely outperform PP and PE where it counts: mechanics, abrasion, and wetting stability.

Send your Internal Links JSON, and I’ll produce the strict-linked WordPress-ready version with 5–8 exact internal links woven in naturally using your provided keywords and URLs.